The hydraulic cylinder is used to transform a pressurised hydraulic

energy into mechanical energy.

Hydraulic cylinders get their power from hydraulic fluid, usually oil.

It consists of a cylinder barrel, in which a piston separates the

tube into two airtight chambers. A system of seals is in charge of

containing the pressurised fluids into the hydraulic cylinder. A piston

rod attached to the piston moves back and forth and allows it to

generate motion of different tools such as the boom, the bucket, the

spreader, the trailer, etc.

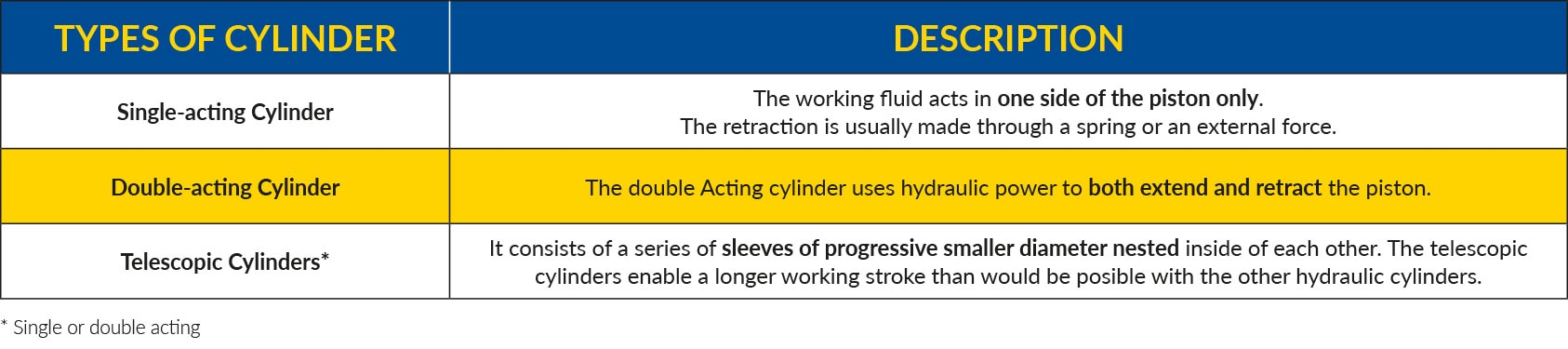

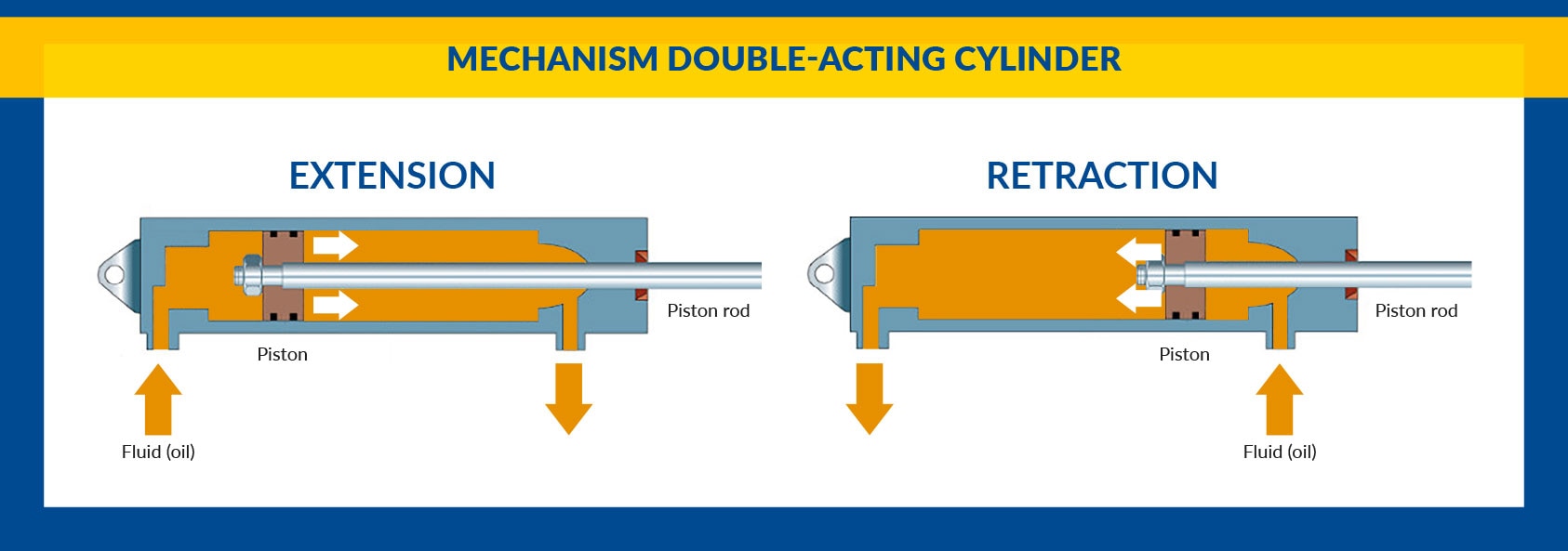

THE DIFFERENT HYDRAULIC CYLINDERS

1.MULTIPLE PERFORMANCE TESTS HAVE BEEN CONDUCTED TO GUARANTEE THE NEW HOLLAND QUALITY:

ENDURANCE TEST Each rod is extended at the middle of a stroke and a pressure of 137 bar is applied on the bore side and 226 bar on the annulus side during 400.000 cycles. After the test, any defect, external or internal leakages or damages on the different parts are identified.

PRESSURE TEST: max pushing work pressure 220 bar.

THREAD RESISTANCE TEST: 6g/6H.

BUCKLING RESISTANCE TEST.

2.RELIABILITY

Reliability of the hydraulic cylinder to high temperatures and corrosion. For most of the cylinders, the common temperature is between -20°C and 90°C with high resistance, but by changing the seals they can be amplified from -40°C to 120°C, thanks to specific treatment such as Oxynit.

3.ACCURACY

Each Genuine cylinder is designed to be perfectly suited to your machine.

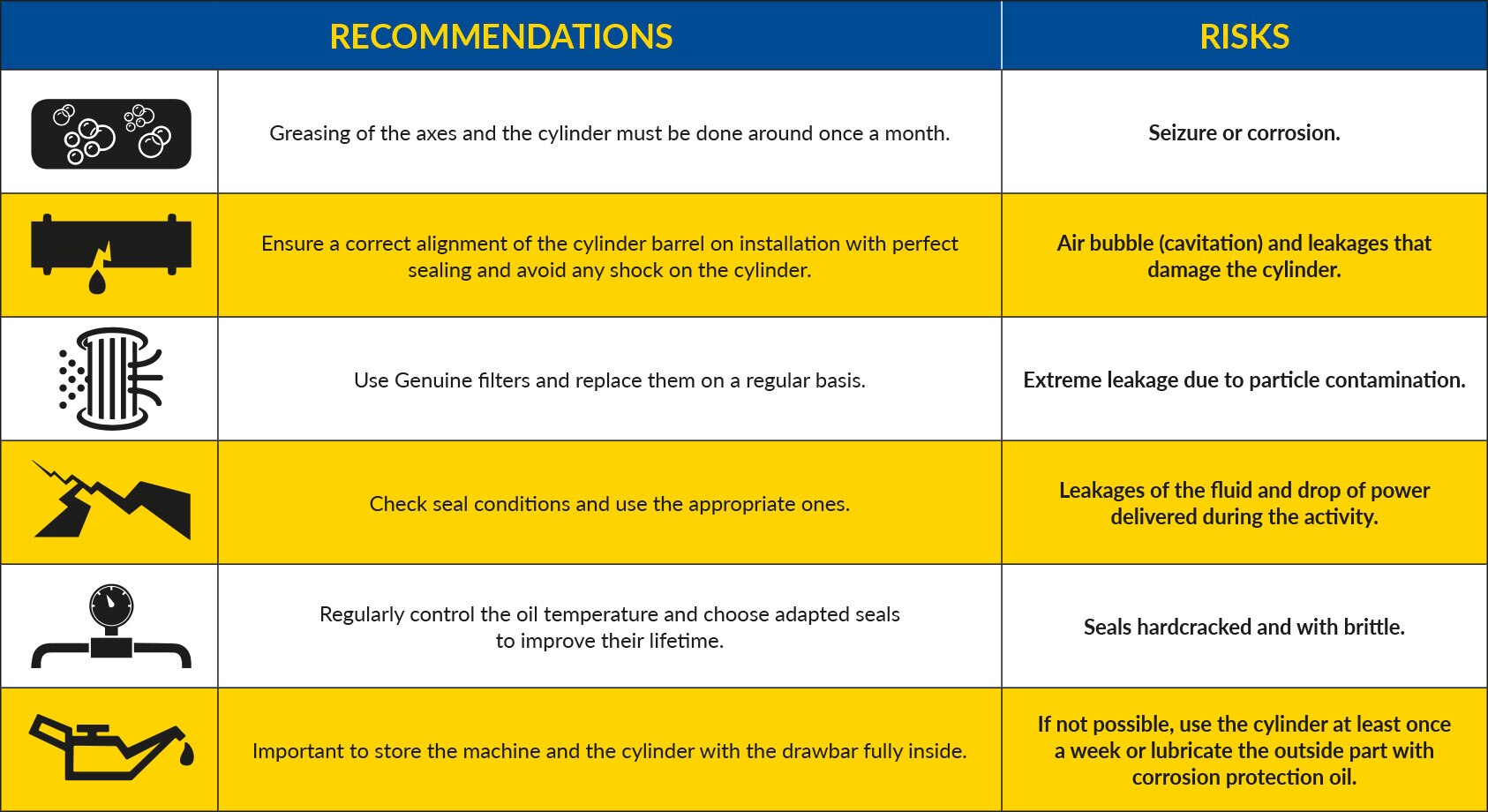

HOW TO KEEP YOUR HYDRAULIC CYLINDER IN A GOOD CONDITION.

DISCOVER MORE

New Holland Agriculture a brand of CNH Industrial © 2019